PARAMOUNT METAL FINISHING COMPANY

Capabilities & Specifications - Plating - Painting - Powder Coating - Certified ISO 9001:2015

1515 West Elizabeth Ave, Linden, NJ 07036 | Tel: 908-862-0772 | Fax: 908-862-9477

Military

Chemical Film MIL-DTL-5541

Painted MIL-DTL-11195

Zinc Phosphate TT-C-490

Painted MIL-DTL-11195

MIL-A-8625

Type II Class 1

MIL-A-8625

Type III Class 2

Munitions require very tight tolerances for the surface coating, whether it be plating, anodizing or painting. These coatings serve a variety of functions such as: bonding surfaces, corrosion protection, oblation characteristics, color coding and wear resistance. The coatings are often critical to the function and performance of the munitions. Paramount Metal Finishing are specialists in customized lines for tight tolerance anodizing, plating and painting in high production.

Paramount Metal Finishing has earned the reputation of having extensive knowledge of finishing munitions.

Some of the approved programs we process include:

- 120mm tank ammo projectile components

- 105mm projectile and shell casings

- Medium caliber: 20mm, 30mm, 40mm and 50mm

- mortar components

- grenade components

- .50 caliber components

Finishings typically used for munitions include:

- Anodizing MIL-A-8625 Type II

- Hardcoat MIL-A-8625 Type III

- Zinc ASTM-B633

- Zinc phosphate TT-C-490, MIL-DTL-16232 Type 2

- Manganese phosphate MIL-DTL-16232 Type M

MILITARY HARDWARE

Ammunition Box

Olive-drab Specialty Coating

Antenna Cover

Green CARC

Radio Housing

Chemical Film / Green CARC

Military munitions, military electronics and military hardware all require a wide range of finishes for specific performance requirements. Military hardware and components are fabricated from many raw materials such as casting, extrusions, machined ferrous and non ferrous materials, and plastic, Invar, Kovar, sheet metal, aluminum, titanium, stainless steel and many other materials. Every material has specific cleaning and coating procedures outlined in applicable military standards or specifications and called out on drawings.

Paramount Metal Finishing has specific processes set up to strictly adhere to the prescribed military standard or specification inclusive of inspecting and testing requirements. Many of our processes are reviewed and approved by government procurement activities.

Government-related activities include:

- First Article Acceptance & Testing (FAAT)

- Government Source Inspection (GSI)

Finishes:

- Anodizing

- Hardcoat anodizing

- Plating (various) see Specifications and Capabilities

- Phosphating ( manganese & zinc )

- Passivation

- Chemical film

Painting & Powder Organic Coatings:

- CARC coatings

- Enamels, lacquers, epoxies

- Dry film lubrication

- Solid film lubrication

- Waxes & oils

- Ink stamp

- Stencil

- Pad printing

- Laser marking

- Inkjet Marking

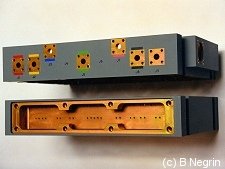

MILITARY ELECTRONICS

Radio Housing

Chemfilm MIL-

CARC Green

Radio Housing

Chemfilm MIL-DTL5541

CARC Black

Electronic Housing

Chemfilm MIL-C5541

Primer / Paint

Capabilities & Specifications - Plating - Painting - Powder Coating - Certified ISO 9001:2015

ITAR Registered

Contact: bnegrin@pmfnj.com

Copyright © 2010 Paramount Metal Finishing